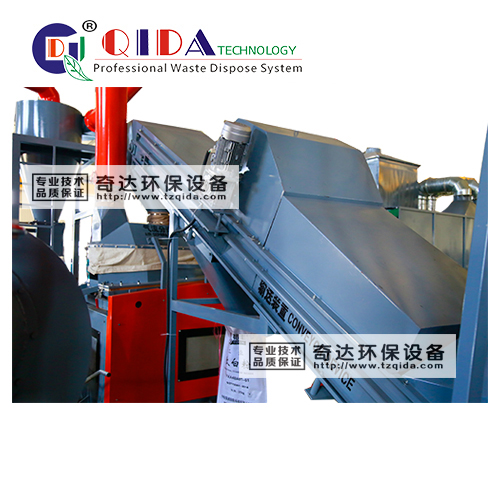

QD-2000A radiator recycling equipment with non-polluted process, using dry crusher, strong magnetic roller separator and air separator, the waste radiators are crushed and sorted.

Obviously compared with manual dismantling which is difficult and requires high labor cost, it will be much easier to operate to obtain renewable resources when processed by this professional equipment.

There are two kinds of the QD-2000A motor rotor recycling machines based on different configurations:

1) simple ( much dust during the whole process );

|

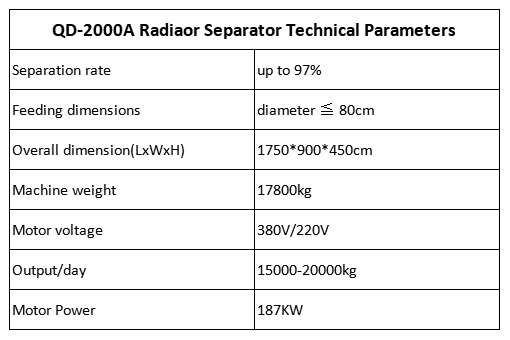

QD-2000A RADIATOR RECYCLING MAHINE |

|

|

Configuration: |

simple |

|

Separation rate: |

≥98% |

|

Processing diameter: |

≦80 cm |

|

Floor area (L*W*H): |

1750cm*900cm*500 cm |

|

Weight: |

15000 KGS |

|

Capacity: |

1200-2000 KGS PER HOUR |

|

Motor power: |

156KW |

2) regular ( less dust during the whole process ).

|

QD-2000A RADIATOR RECYCLING MAHINE |

|

|

Configuration: |

regular |

|

Separation rate: |

≥98% |

|

Processing diameter: |

≦80 cm |

|

Floor area (L*W*H): |

1800cm*1450cm*450cm |

|

Weight: |

17800 KGS |

|

Capacity / hour: |

1200-2000 KGS PER HOUR |

|

Motor power: |

210KW |

You will get copper, iron, aluminum, all are separated very well. The separation rate could be up to 98%.

中文

中文 ENGLISH

ENGLISH